US Stock SFX-4000B EDM Broken Tap Remover Machine M2-M36 Portable Machine Tap Burner Tap Buster

US Stock SFX-4000B EDM Broken Tap Remover Machine M2-M36 Portable Machine Tap Burner Tap Buster

US Stock, free shipping

Free Shipping!

Couldn't load pickup availability

With the rapid development of automation equipment, the high demand for product precision, and the extensive use of difficult-to-cut materials in machining, broken tools often get stuck in workpieces, significantly affecting the defect rate of products. Common methods for removing broken taps and drills include smashing the items by hand, screwing them out after welding, or even using acid corrosion or flame cutting. These methods, however, are inefficient and can damage the workpieces.

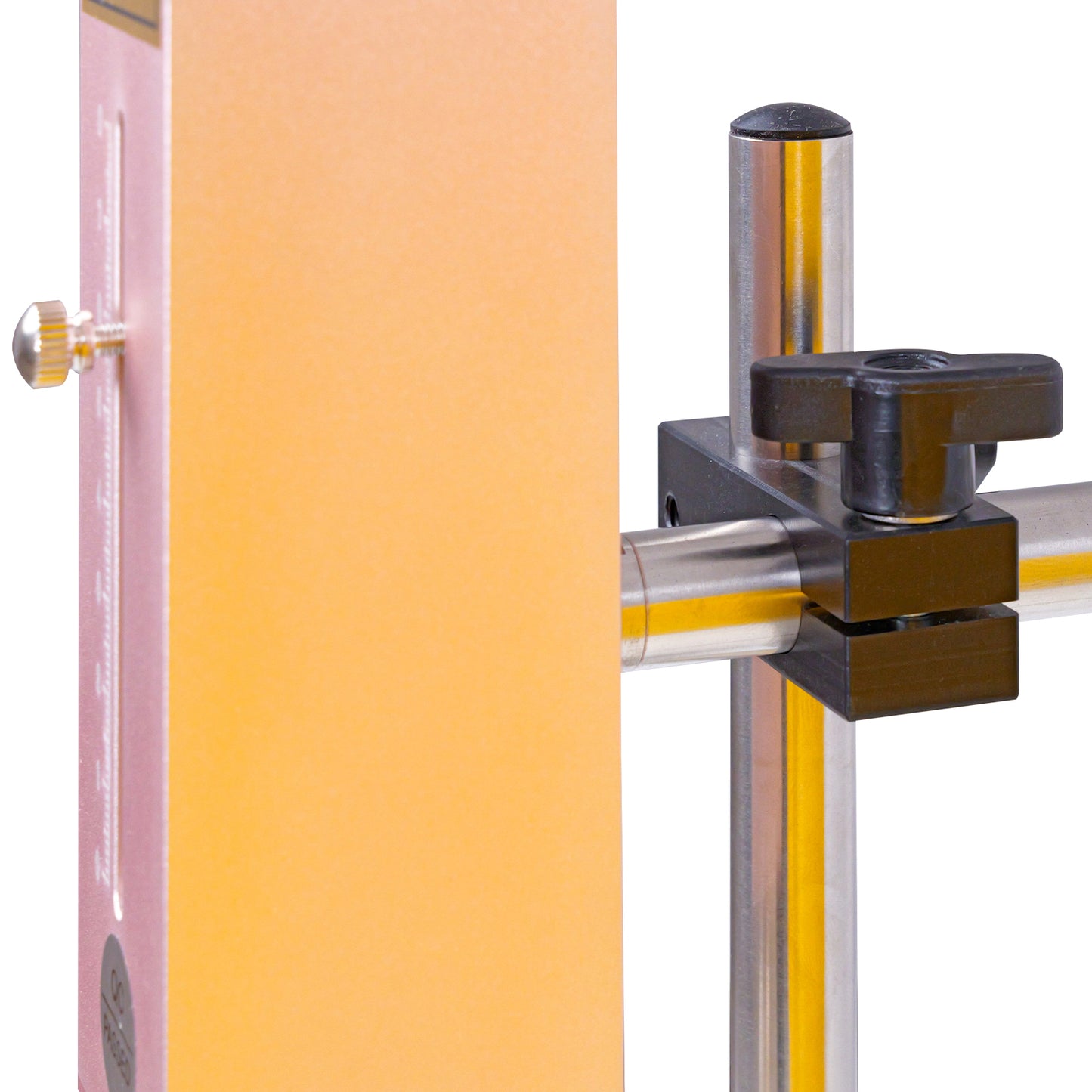

The SFX-4000B Broken Tap Remover machine can quickly remove broken taps, drills, drifts, screws, and plug gauges without damaging the workpiece. It easily processes workpieces of any size and is especially effective for large machine tools. The machine's integrated design includes a storage space at the bottom of the power box, making it convenient for managing attachments. With its high processing efficiency, it can remove broken taps and screws, and is particularly effective for processing markings.

Specification:

Model: SFX-4000B

Application: Remove Dia M2-M36 (5/64''-1-57/64″) broken taps, drill, drift, screw, plug gauge

Depth Setting: YES

Input Power: 3000W

Electrical Requirement: 110V/220V

Electrode Holder Diameter: 2-13 mm

Working Liquid: Tap Water ( Pure Water /Distilled Water is better )

Max Process Depth of Spindle Servo: 70mm

Processing Speed: 2 mm/min(Electrode φ5; 1mm/min (Electrode φ12)

Working Head: DK8 315*50*50mm

N.W: 22 kg

G.W: 26 kg

Function and Features:

SFX-4000B Tap Buster/Metal Disintegrator machine abides by the principle of spark erosion to remove broken tools, no direct contact, no external forces and damage to the work pieces.

Portability: Light weight. Small Size. Carrying handle is on the top of the power case.

Convenient Operation: The magnetic base could be absorbed on work piece to finish processing easily.

Economical and Convenient: The working liquid is ordinary tap water. Power consumption is moderate. The inlet pipe is detachable.

Wide Processing Range: Broken taps and drills (conductive material )above diameter 2mm (2mm is included)

Long Working Hours: A cooling fan installed ensures the ventilation, which keeps the machine working continuously.

Drilling non-precision holes and marking.

Integrated case for easy storage. The work head with vibration function.

More applications: non-precision holes and marking.

Processing Method:

1.The common ground of tap, drill, etc. tools is that the central part is solid. So the tap or drill could be removed out by smashing the central part. Before processing, please clean up the rust or oxide layer. When processing deep hole or work piece in deep channel, hollow electrode and high pressure water pump could help increasing the pollution discharge speed.

2. When the diameter of the screw is too big or its strength grade is over 8.8, general processing method is unsuitable. You can process a groove of 2-3 mm depth with a sheet electrode. Then unscrew it with a screwdriver or hexagon spanner. If the processing position is too deep for general screw extractor, the hexagon spanner would help.

3. Selection of Electrode Size: Generally, the diameter of electrode recommended is half of the size of broken items.

Packing and shipping :

The machine is in NY/CA/NJ, USA and our factory China. It takes about 5 days to your door. We will deliver the Tap Buster/Metal Disintegrator Machine within 2 days via International express after received your full payment and you will receive the goods about 5-10 days at your door.

Share