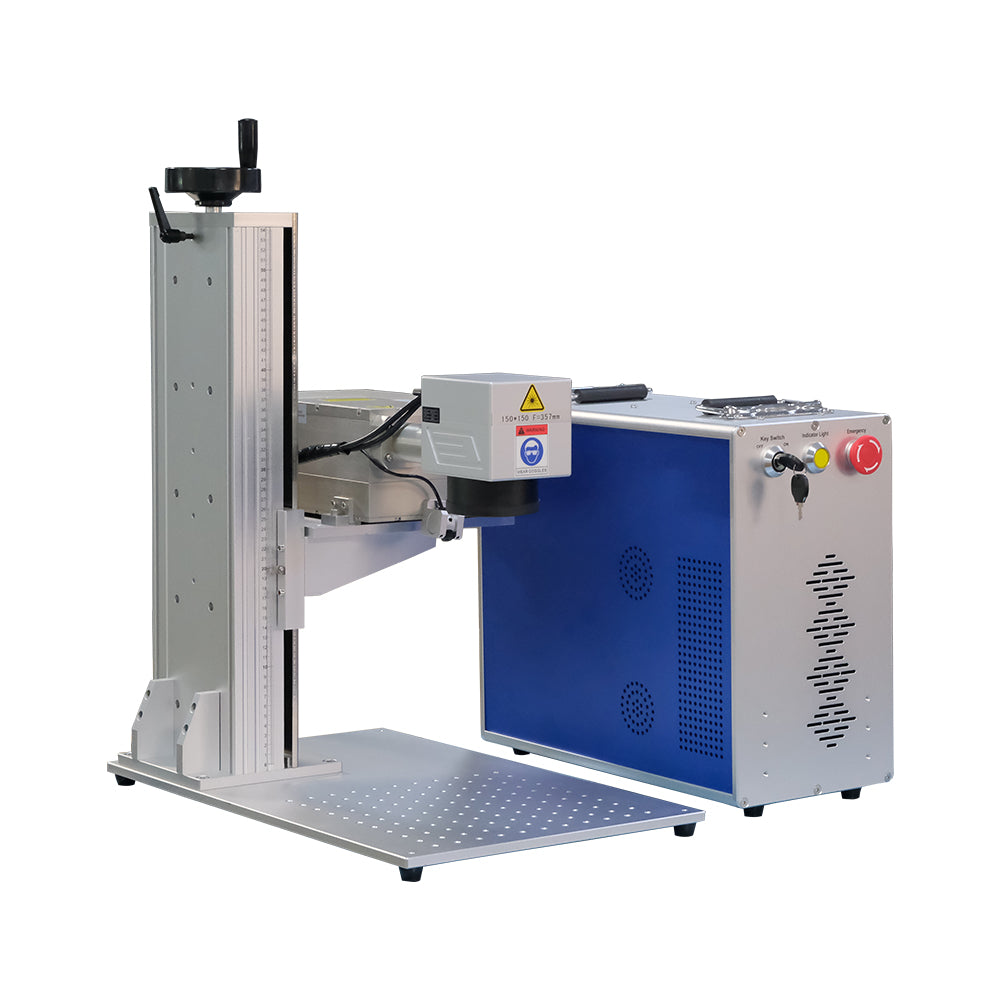

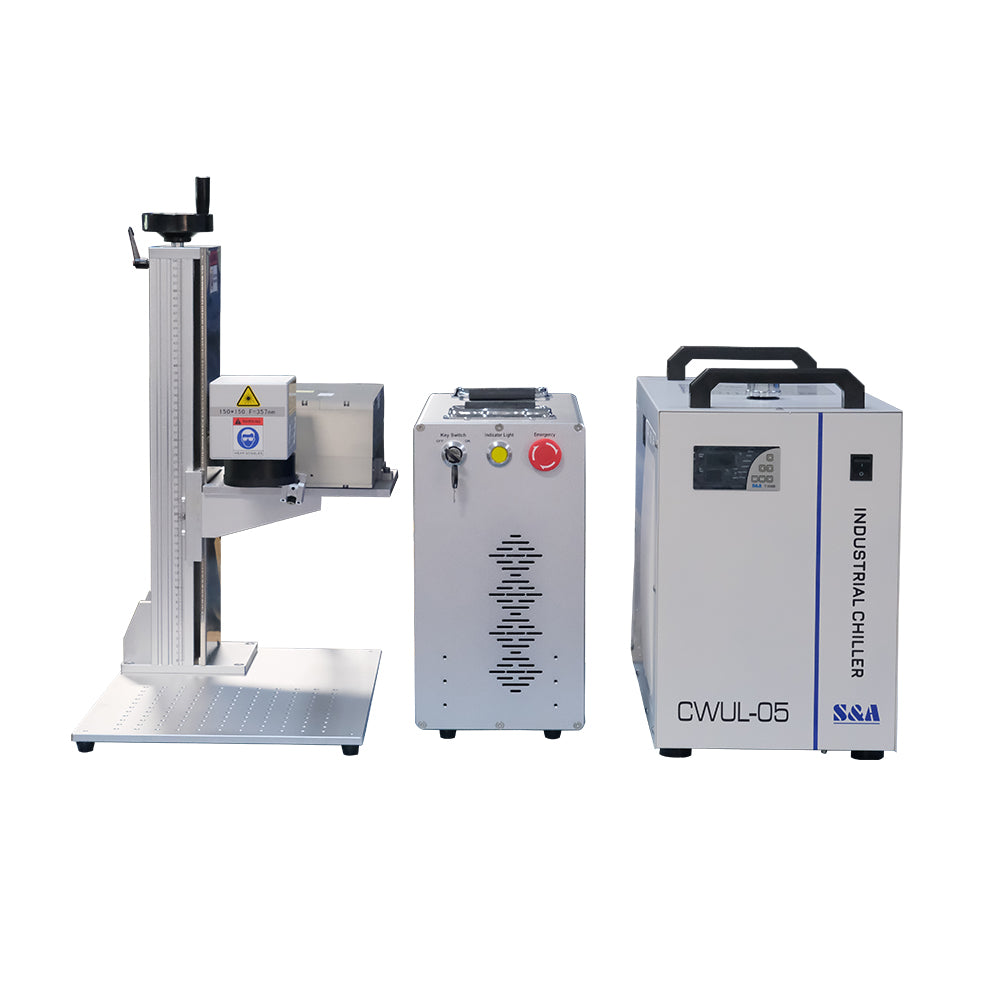

SFX Laser 3W/5W/10W/15W UV laser Engraver JPT UV Laser Marker Laser Marking Machine with S&A Water Chiller

SFX Laser 3W/5W/10W/15W UV laser Engraver JPT UV Laser Marker Laser Marking Machine with S&A Water Chiller

10% Off

Free Shipping!

Couldn't load pickup availability

SFX Laser 3W/5W/10W/15W UV laser Engraver JPT UV Laser Marker Laser Marking Machine with S&A Water Chiller

Configuration:

UV laser Engraver UV Laser Marker Laser Marking Machine with S&A Water Chiller

Laser Power: 3W/5W/10W/15W

Laser Source: JPT Seal-355-3C/JPT Seal-355-5C/JPT Seal-355-10S/JPT Seal-355-15S

Laser Wavelength: 355nm

Beam Quality: M2<1.2

Laser Repetition Frequency: 20-200KHZ@JPT

Marking Area: 110*110mm/150*150mm/175*175mm/220*220mm/300*300mm

Marking Speed: ≤8000mm/s

Engraving Depth: ≤0.01mm-0.5mm(It depends on the material)

Min. Line Width: 0.01mm

Min. Character: 0.15mm

Repeat Accuracy:±0.001mm

Demand for Electricity: 110V/60HZ 220V/50HZ

Power Consumption: ≤1500W

Cooling Way: Water-Cooling (We also offer air-cooled UV laser marking machines at the same price as our water-cooled models. Simply contact us to request this option, or just make a note when placing your order.)

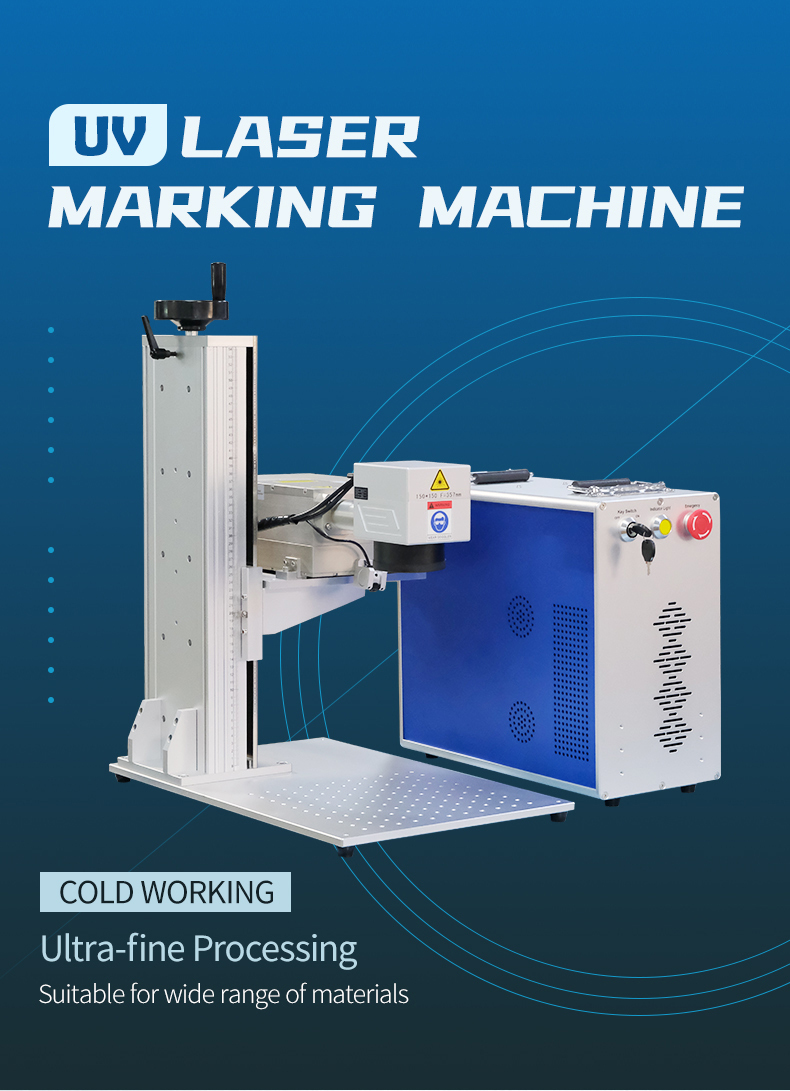

Wide Application:

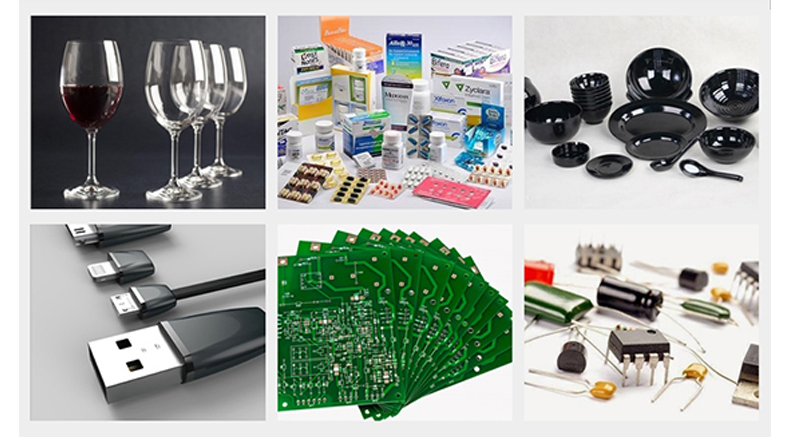

UV Fiber Laser Engrave /laser marking machine is mainly based on its unique low- power laser beam, especially suitable for the high-end market of ultra- -fine processing. It is very suitable for cosmetics, drugs, food and other macro-molecule material packaging surface marking. The marking effect is fine, clear and firmly, and better than ink jet code, no pollution. It is widely used in marking and slicing of flexible PCB, silicon wafer micro-hole, blind hole processing, LCD glass qr code, glassware surface punching, metal surface coating, plastic keys, electronic components, gifts, communication equipment, construction materials, rubber and other non-metallic materials.

Working Principle:

The processing process of the ultraviolet laser marking machine is called the "photo etching" effect.The "cold processing" has a very high load energy (ultraviolet) photon, which can break the chemical .bond in the material or the surrounding medium to cause the material to undergo non-thermal process damage , The inner layer and nearby areas do not produce heating or thermal deformation, etc.The final processed material has smooth edges and extremely low carbonization, so the fineness and thermal influence are minimized.

The reaction mechanism of ultraviolet laser processing is realized by photo chemical ablation, that is,relying on laser energy to break the bonds between atoms or molecules, so that they become small molecules and vaporize and evaporate.The focused spot is extremely small, and the processing heat-affected zone is minimal, so it can be used for ultra-fine marking and special material marking.

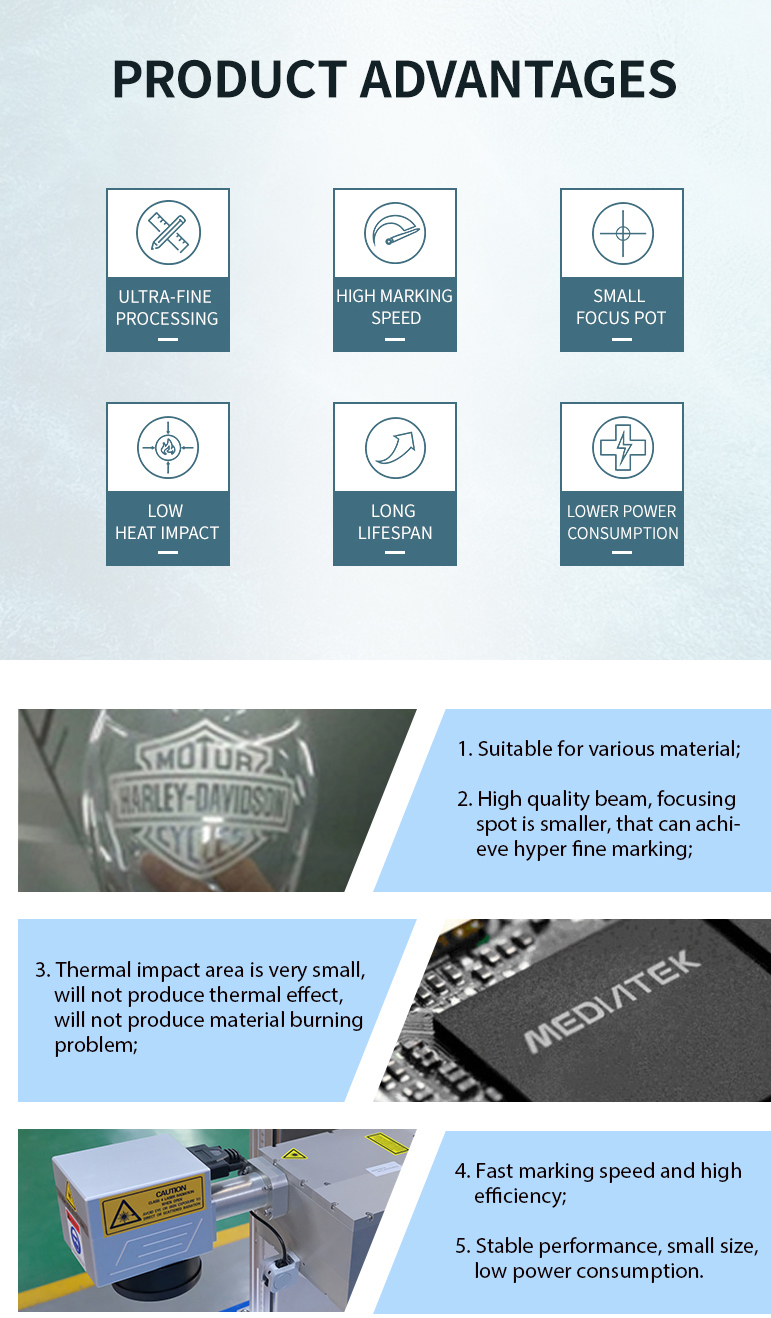

Advantage:

1. Suitable for various material

2. High quality beam, focusing spot is smaller, that can achieve hyper fine marking

3. Thermal impact area is very small, will not produce thermal effect and material burning problem

4. Fast marking speed and high efficiency.

5. Stable performance, small size and low power consumption.

Warranty and Shipping:

Free Shipping by DHL/UPS including tariffs and broke fees around 7-10 days. No Import Duty for American Customers.

1 Year Warranty, After Sales Center in NY, US. Offer Remote Assistance for Operation Issues. Lifetime Online Technical Support.

Company Strength Display

Share